Meloon Foundries llc

INFO

Partner Foundry

© 2025 Meloon Foundries LLC

Website & SEO By: MI Digital Solution

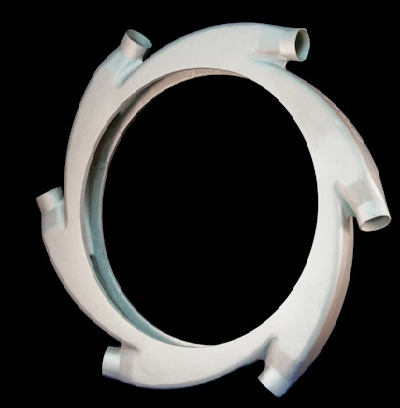

Meloon Foundries Inc. was approached by a plastic film manufacturer to mold 30 aluminum plenums. The plenums, which were made of SR319 aluminum, were no-bake molded on a continuous no-bake mixing production line, and then shot blasted.

Standard tolerances of +/- .030” were held. The plenums were .125″-.500″ thick, had an outside diameter of 48″ and were delivered ready for powder coating by the customer. Product ranges in size from 24″-60″.

For more information about our other services, please contact Meloon Foundries.

| Product Name | Aluminum Plenum |

| Product Description | This aluminum plenum is used to inject air into a film making machine. |

| Capabilities Applied/Processes | Primary: No-Bake Molding, No Bake Core Secondary: |

| Equipment Used to Manufacture Part | Continuous No-Bake Mixing Production Line |

| Overall Part Dimensions | O.D.: Ø48″ Thickness: .125″-.500″ |

| Tightest Tolerances | ±.030″ |

| Material Used | SR319 Aluminum |

| In process testing/inspection performed | Visual Inspection |

| Estimated Part Weight | 114 lbs |

| Industry for Use | Plastic Film Machine |

| Volume | 30 Annually |

| Standards Met | Customer Supplied Print |

Meloon Foundries specializes in casting aluminum and copper-based alloys. Over 40 different alloys are cast for commercial applications serving more than 200 customers in the United States.

© 2025 Meloon Foundries LLC

Website & SEO By: MI Digital Solution