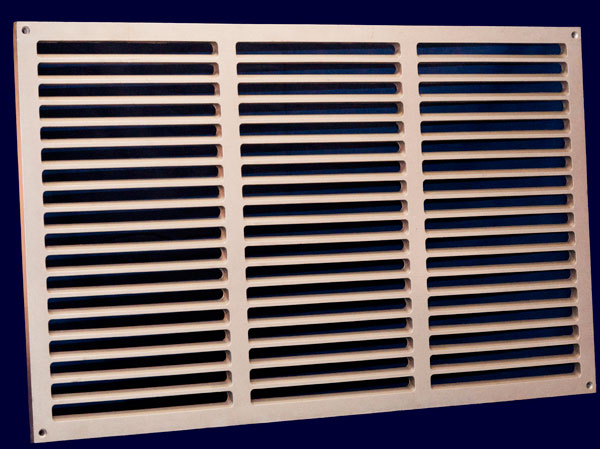

A customer in the architecture industry approached Meloon Foundries Inc. to manufacture aluminum window grates using the no-bake molding process. The corrosion resistant, 356F aluminum window grates, which measured 68″ long, 48″ wide and 1″ thick, were created on a continuous no-bake mixer production line.

After molding, the grates were machined, shot blasted and then painted. Standard tolerances of +/- .030” were held. As requested by the client, we produced 1,800 of the 82 lbs grates over a six-month period.

To learn about our other services, please contact Meloon Foundries.

No Bake Molding Project Highlights

| Product Name | Aluminum Window Grate | Aluminum Window Grate |

| Product Description | This aluminum window grate is hung over a window to give an industrial look to the building. | This aluminum window grate is hung over a window to give an industrial look to the building. |

| Capabilities Applied/Processes | Primary: No-Bake Molding | Secondary: Machining Stainless Steel Shot Blasting Painting |

| Equipment Used to Manufacture Part | Continuous No-Bake Mixer Production Line | |

| Overall Part Dimensions | Length: 68″ Width: 48″ Thickness: 1″ 3 Sections of 19 Openings | |

| Tightest Tolerances | ±.030″ | |

| Material Used | 356F Aluminum | |

| Features | Corrosion Resistant | |

| In process testing/inspection performed | Visual Inspection and Straightening | |

| Estimated Part Weight | 82 lbs | |

| Industry for Use | Architectural | |

| Volume | 1,800 Over 6 Months | |

| Standards Met | Customer Supplied Print |

Meloon Foundries specializes in casting aluminum and copper-based alloys. Over 40 different alloys are cast for commercial applications serving more than 200 customers in the United States.